Vespa GTS Super 300 ie - Service manual > Splitting the crankcase halves

Vespa GTS Super 300 ie - Service manual > Splitting the crankcase halves

- Before opening the crankcase, it is advisable to check the axial clearance of the crankshaft. To do this, use a plate and a support with appropriate tool dial gauge.

- Upper clearances are an indication of wear on the surfaces of the crankshaft casing support.

- Remove the 10 crankshaft coupling screws.

- Separate the crankcase while keeping the crankshaft in one of the two halves of the crankcase.

- Remove the crankshaft.

- Remove the half crankcase coupling gasket.

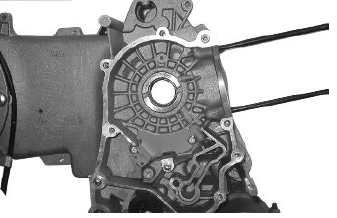

- Remove the two screws and the internal cover shown in the diagram.

- Remove the oil guard on the flywheel side.

- Remove the oil filter fitting shown in the diagram.

- Check the axial clearance on the connecting rod.

- Check the radial clearance on the connecting rod.

- Check the surfaces that limit the axial free-play are not scored and measure the width of the crankshaft between these surfaces, as shown in the diagram.

- If the axial clearance between crankshaft and crankcase is exceeding and the crankshaft does not have any defect, the problem must be due to either excessive wear or wrong machining on the crankcase.

- Check the diameters of both the bearings of the crankshaft in accordance with the axes and surfaces shown in the figure. The half-shafts are classified in two categories Cat. 1 and Cat. 2 as shown the chart below.

CAUTION

THE CRANKSHAFT CAN BE REUSED WHEN THE WIDTH IS WITHIN THE STANDARD VALUES AND THE SURFACES SHOW NO SIGNS OF SCORING.

CAUTION

WHILE OPENING THE CRANKCASES AND REMOVING THE CRANKSHAFT, CHECK THAT THE THREADED SHAFT ENDS DO NOT INTERFERE WITH THE MAIN BUSHINGS.

FAILURE TO OBSERVE THIS PRECAUTION CAN DAMAGE THE MAIN BUSHINGS.

CAUTION

KEEP THE CRANKSHAFT IN ONE OF THE TWO HALVES OF THE CRANKCASE WHEN SEPARATING IT. IF YOU FAIL TO DO THIS, THE CRANKSHAFT MIGHT ACCIDENTALLY FALL.

N.B.

WHEN MEASURING THE WIDTH OF THE CRANKSHAFT, MAKE SURE THAT THE MEASUREMENTS ARE NOT MODIFIED BY THE RADIUSES OF FITTINGS WITH THE CRANKSHAFT BEARINGS.

N.B.

TO MEASURE WEAR LIMITS AND COUPLING CLEARANCES, SEE THE SPECIFICATIONS CHAPTER.

Inspecting the crankshaft alignment

N.B.

TO MEASURE WEAR LIMITS AND COUPLING CLEARANCES, SEE THE SPECIFICATIONS CHAPTER.

Inspecting the crankcase halves

- Before proceeding to check the crankcase halves, thoroughly clean all surfaces and oil ducts.

- On the transmission-side crankcase half, take particular care when handling the oil pump compartment and the oil ducts, the by-pass duct, the main bushings and the cooling jet on the transmission side (see diagram).

- Take particular care, also, that there are no signs wear in the oil by-pass valve housing (see Chapter Lubrication), as this could prevent a good seal in the piston, which regulates the oil pressure.

- On the flywheel side crankcase half, take particular care cleaning the oil ducts for the main bushings, the oil duct for the jet that lubricates the cylinder head and the oil drainage duct at the flywheel side oil seal.

- Inspect the coupling surfaces on the crankcase halves for scratches or deformation, taking particular care with the cylinder/crankcase surfaces and the crankcase halves surfaces.

- Defects in the crankcase coupling gasket between the crankcase halves or the mating surfaces shown in the diagram, could cause a drop in the oil pressure lubricating the main bushings and connecting rod.

- Check the main bearing seats that limit axial clearance in the crankshaft show no signs of wear.

The dimension between these seats is measured by way of the procedure described previously for measuring the crankshaft axial clearance and dimensions.

N.B.

THE JET IS FED THROUGH THE MAIN BUSHINGS. PROPER OPERATION OF THIS COMPONENT IMPROVES PISTON CROWN COOLING. CLOGGING HAS EFFECTS THAT ARE DIFFICULT TO DETECT (PISTON TEMPERATURE INCREASE).

FAILURE OR LEAKS CAN CAUSE A CONSIDERABLE DROP IN THE LUBRICATION PRESSURE FOR MAIN BUSHINGS AND CONNECTING ROD.

N.B.

THE HEAD LUBRICATION CHANNEL IS PROVIDED WITH A SHUTTER JET; THIS GIVES A "LOW PRESSURE" HEAD LUBRICATION; THIS CHOICE WAS MADE TO REDUCE THE OIL TEMPERATURE IN THE SUMP. THE JET CLOGGING IMPAIRS THE HEAD LUBRICATION AND THE TIMING MECHANISMS. A JET FAILURE CAUSES A DECREASE OF THE MAIN BUSHING AND CONNECTING ROD LUBRICATION PRESSURE.

Inspecting the crankshaft plain bearings

- To obtain a good bushing lubrication it is necessary to have both an optimal lubricating pressure and a good oil flow rate; the bushings must be correctly positioned so as not to obstruct the oil supply channels.

- The main bushings are comprised of two half-bearings, one with holes and channels for lubrication whereas the other is solid.

Characteristic

Lubrication pressure

3.5 to 4 bar

- The solid half-bearing is intended to stand the thrusts caused by combustion, and for this reason it is arranged opposed the cylinder.

- To prevent shutters in the oil feeding channels, the matching surface of the two half-bearings must be perfectly orthogonal to the cylinder axis, as shown in the figure.

- The oil feeding channel section is also affected by the bushings driving depth compared with the crankshaft axial clearance of the limiting surface.

N.B.

TO MEASURE WEAR LIMITS AND COUPLING CLEARANCES, SEE THE SPECIFICATIONS CHAPTER.

Refitting the crankcase halves

- Fit the internal shield by locking the two screws to the prescribed torque.

- Fit the oil filter fitting and tighten it to the prescribed torque.

- Position the oil pre-filter element as shown in the picture.

- Place a new gasket on one of the crankcase halves, preferably on the transmission side, together with the alignment dowels.

- Lubricate the main bushings and insert the crankshaft in the transmission side crankcase half.

- Reassemble both crankcase halves.

- Fit the 10 screws and tighten them to the specified torque.

- Fit a new O-ring on the pre-filter and lubricate it.

- Insert the filter on the engine with the relative cap.

Tighten to the prescribed torque.

Locking torques (N*m)

Internal engine crankcase bulkhead (transmission- side half shaft) screws 4 to 6 Engine-crankcase coupling screws 11 ÷ 13 Oil filter on crankcase fitting 27 - 33 Engine oil drainage plug/ mesh filter 24 to 30

See also:

Vespa GTS Super 300 ie - Service manual > Studs

Vespa GTS Super 300 ie - Service manual > Studs

Check that the stud bolts have not worked loose from their seat in the crankcase. Check the depth of stud bolt driving with a gauge, as indicated in the picture. If it varies significantly from the driving depth indicated, it means that the stud bolt has yielded.